Common Concrete Issues and Repair Solutions

Over time, concrete surfaces such as driveways, walkways, and patios can develop cracks, chips, or flaking due to weather conditions, heavy loads, or ground shifts. Addressing these issues promptly not only enhances the appearance of your property but also prevents further deterioration. We offer a range of in-stock top-quality Quikrete products to help you repair and maintain your concrete sur-faces effectively and on your own!

1. Repair Cracks in Concrete Surfaces Such As Sidewalks, Patios, Driveways, and Masonry Walls

What causes small cracks in concrete surfaces?

- Freeze-thaw cycles

- Heavy loads

- Tree roots

- Gound movements

We recommend using QUIKRETE® Concrete Repair Caulk for repairing small cracks caused by these conditions. This product is specifically formulated to seal and protect both vertical and horizontal cracks in concrete surfaces. It features a textured finish that blends well with existing concrete, and its flexible, weather-resistant formulation helps prevent further water intrusion, freeze damage, and erosion. Whether you’re patching cracks in sidewalks, driveways, or foundation walls, QUIKRETE® Concrete Repair Caulk provides a long-lasting, easy-to-apply solution to restore strength and appearance.

QUIKRETE®

Concrete Repair Caulk

10 oz. White. Ideal for vertical and horizontal applications. A textured caulk that permanently seals and waterproofs cracks in concrete surfaces. Weather resistant. Dries quickly. (#6912711)

Watch How-To Video

Repair Cracks

- Clean the Area

Remove any loose debris, dirt, or unsound concrete using a chisel and wire brush. - Apply The Material

For narrow cracks, apply QUIKRETE® Concrete Repair Caulk directly into the crack. - Finish the Surface

Smooth the repair material with a trowel and allow it to cure as per product guidelines.

2. Make Thin Repairs To Cracked, Chipped or Spalled (Flaking) Concrete Floors, Sidewalks, or Steps

What causes concrete to crack or chip?

- Impact damage

- Wear and tear

What causes concrete to spall? (flake)

- Freeze-thaw cycles

- De-icing salts

We recommend QUIKRETE® Vinyl Concrete Patch for making thin repairs to cracked, chipped or spalled concrete surfaces. This high-performance patching compound is designed specifically for thin applications and works great on floors, sidewalks, and steps. It only requires water to activate, making it easy to mix and apply. Once in place, it forms a durable bond that resists shrinkage and cracking, ensuring a smooth, long-lasting finish. Whether you’re fixing surface chips or hairline cracks, QUIKRETE® Vinyl Concrete Patch is a go-to solution for restoring the look and integrity of your concrete.

QUIKRETE®

Vinyl Concrete Patcher

10 lb. tub. Gray. Multi-purpose concrete repair material with strong adhesive properties. Trowels to a feather edge of 1/16″ (1.6 mm). Made of a special blend of exterior grade vinyl resin, fine sand, and portland cement. Just add water. (#7283237)

Watch How-To Video

Repair Chipped or Broken Edges

1. Clean and Prepare

Remove any loose material and clean the area thoroughly.

2. Mix Repair Material

Prepare QUIKRETE® Quick-Setting Cement according to the instructions.

3. Apply and Shape

Press the mixture into the damaged area, sculpting it to match the original contour.

4. Cure

Keep the area moist for several days to ensure proper curing.

Repairing Spalled Surfaces

1. Surface Preparation

Clean the area to remove any loose or flaking concrete.

2. Mix Patching Compound

Prepare QUIKRETE® Vinyl Concrete Patcher as per instructions.

3. Application

Trowel the patcher onto the spalled area, ensuring a smooth and even finish.

4. Curing

Allow the patched area to cure properly before exposing it to traffic.

3. Repair Leaks In Concrete Masonry, Walls, Swimming Pools, and Foundations

What causes water leaks in concrete?

- Hydrostatic pressure

- Cracks in concrete or mortar joints

- Poor drainage or waterproofing

- Aging or weathered surfaces

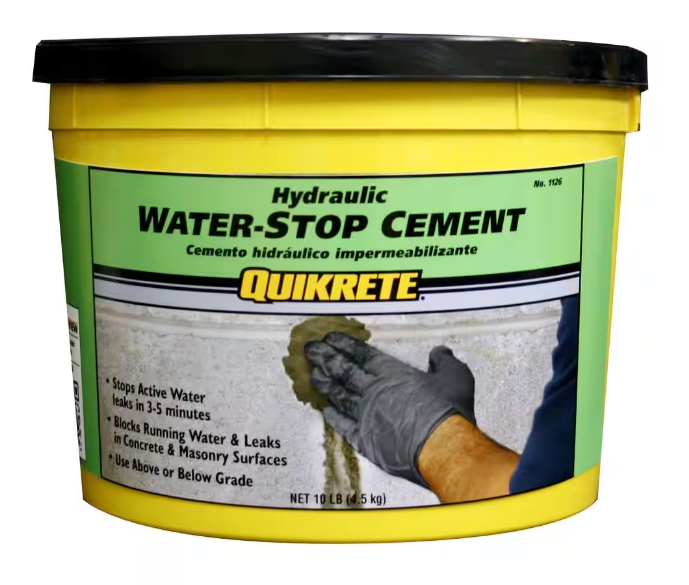

We recommend QUIKRETE® Hydraulic Water-Stop Cement for sealing active water leaks in con-crete and masonry. This fast-setting repair material is specially formulated to block running water and stop leaks instantly—even under pressure. It sets in 3 to 5 minutes and expands as it hardens, ensuring a watertight seal in cracks, holes, and mortar joints. Ideal for use on basement walls, retaining walls, swimming pools, foundations, and any surface where water intrusion is a concern, QUIKRETE® Water-Stop Cement offers a permanent, high-strength solution to keep moisture out and protect your structure for the long term.

QUIKRETE®

Hydraulic Water-Stop Cement

10 lb. tub. Rapid setting, high strength repair material designed to plug leaks instantly in concrete and masonry. Sets in 3-5 minutes and can be used above and below grade. Designed to block running water or leaks in cracked masonry or concrete surfaces. (#8435794)

Step-by-Step Repair Guide: Sealing Water Leaks in Concrete and Masonry

What You’ll Need:

- QUIKRETE® Hydraulic Water-Stop Cement

- Mixing bucket

- Trowel or gloved hand

- Safety goggles & rubber gloves

- Wire brush or chisel

- Clean water

1. Prepare the Surface

Use a chisel and hammer or wire brush to enlarge the crack or hole to a minimum depth and width of ¾ inch. The edges should be square or undercut (not V-shaped), which helps the repair material lock in more securely. Tip: Remove all loose or crumbling material, dirt, and dust from the repair area.

2. Mix the Product

In a clean container, quickly mix small amounts of Water-Stop Cement with cold, clean water to a putty-like consistency.

You’ll have only 2–3 minutes of working time, so only mix what you can apply immediately.

Mix Ratio: Approximately 4 parts powder to 1 part water (always follow package instructions for exact proportions).

3. Apply Immediately

Using a gloved hand or trowel, press the mixture firmly into the crack or hole. Hold it in place for 2–3 minutes, or until it has hardened.

Important: If the area has active water flow, press the material into the leak and hold it tight until it stops.

4. Shape and Smooth

Once the material has set, smooth it to match the surrounding surface using a trowel. Make sure the edges are sealed and flush with the existing concrete.

5. Allow to Cure

Although Water-Stop Cement sets in just a few minutes, allow the repair to fully cure for 24 hours before applying any waterproof coatings or paint.

Helpful Tips:

Work in small batches due to the rapid setting time.

Always wear safety gear—this product is caustic and can irritate skin and eyes.

For ongoing leak problems, consider additional drainage or waterproofing improvements.

Expert Tips for Successful Concrete Repairs:

Proper Surface Preparation: Ensure all loose and unsound materials are removed before applying repair products. Quikrete

Moisture Control: Dampen the repair area before application, but avoid standing water.

Curing: Follow the recommended curing procedures to achieve optimal strength and durability.

Safety First: Always wear appropriate safety gear, including gloves and eye protection, when handling repair materials.

Why Choose Curtis Lumber for Your Concrete Repair Needs?

Quality Products: We offer a curated selection of top-quality concrete repair products from trusted brands like QUIKRETE®.

Expert Advice: Our knowledgeable staff can provide guidance and recommendations tailored to your specific repair projects.

Convenience: With multiple locations and a comprehensive inventory, we make it easy for you to find the right products for your needs.

For Additional HOW-TO QUIKRETE® Concrete Building and Repair projects, visit: https://www.quikrete.com/athome/videos.asp